Your Guide to Bulk Metal Fabrication

Bulk metal fabrication drives modern manufacturing, turning raw metal into reliable parts and structures used across industries. From automotive components to industrial equipment, this process supports the production of high-quality products at scale. Understanding how bulk metal fabrication works helps clarify how precision, efficiency, and durability are achieved in everyday applications, and why choosing the right fabrication partner matters for project success.

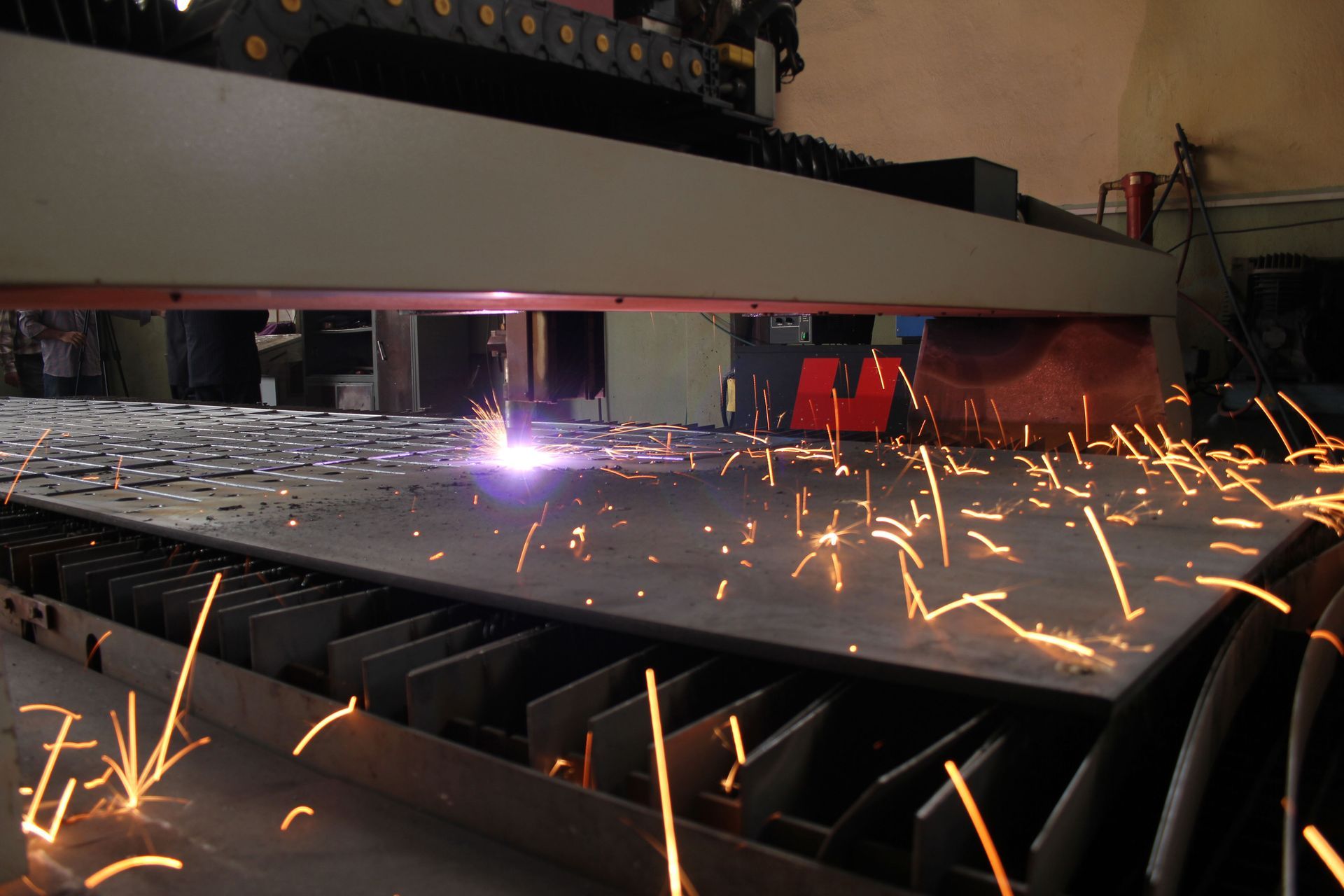

Cut Metal With Precision

The first step in bulk metal fabrication is cutting raw materials into accurate shapes and sizes. This process often uses water jet cutting and laser cutting, which deliver tight tolerances and clean edges. These methods are especially valuable for complex designs that require consistent accuracy across large production runs. With precision cutting, material waste is minimized, and production timelines stay on track.

Form Metal With Consistency

After cutting, the metal is formed into the required design through bending, shaping, and pressing techniques. Sheet metal shearing and metal forming create the specific angles and curves needed for functional parts. According to Metalcon.com, most metal fabrication uses sheet metal that can be up to a quarter inch thick, allowing for both flexibility and strength in the final product. With consistent forming processes, manufacturers can produce uniform parts that meet tight specifications every time.

Assemble Components With Strength

Once parts are cut and formed, they move into assembly, where multiple pieces are joined together to create finished products. Assembly capabilities include welding and fastening techniques that ensure structural integrity and long-term durability. This stage is crucial for creating finished products that perform reliably in demanding environments.

Finish Metal With Durability

Finishing services add the final layer of protection and appearance to fabricated components. Coating, polishing, and other finishing methods improve resistance to corrosion, enhance visual appeal, and extend service life. A high-quality finish helps metal parts hold up under heavy use while maintaining a professional look.

Bulk metal fabrication is a detailed process that relies on precision cutting, consistent forming, strong assembly, and durable finishing to deliver dependable components. For manufacturing needs that require large-scale production and reliable results, Denali MetalWorks can help guide the project from start to finish with confidence. Contact us today to discuss your next fabrication project and see how we can support your goals.

Share On: