Industry Trends in Metal Parts Manufacturing: What You should Know

The metal parts manufacturing industry is a cornerstone of modern industrialization, playing a critical role in the production of everything from complex engines to household appliances. As technology advances and market demands shift, staying informed about the latest trends becomes essential for businesses and professionals within the sector.

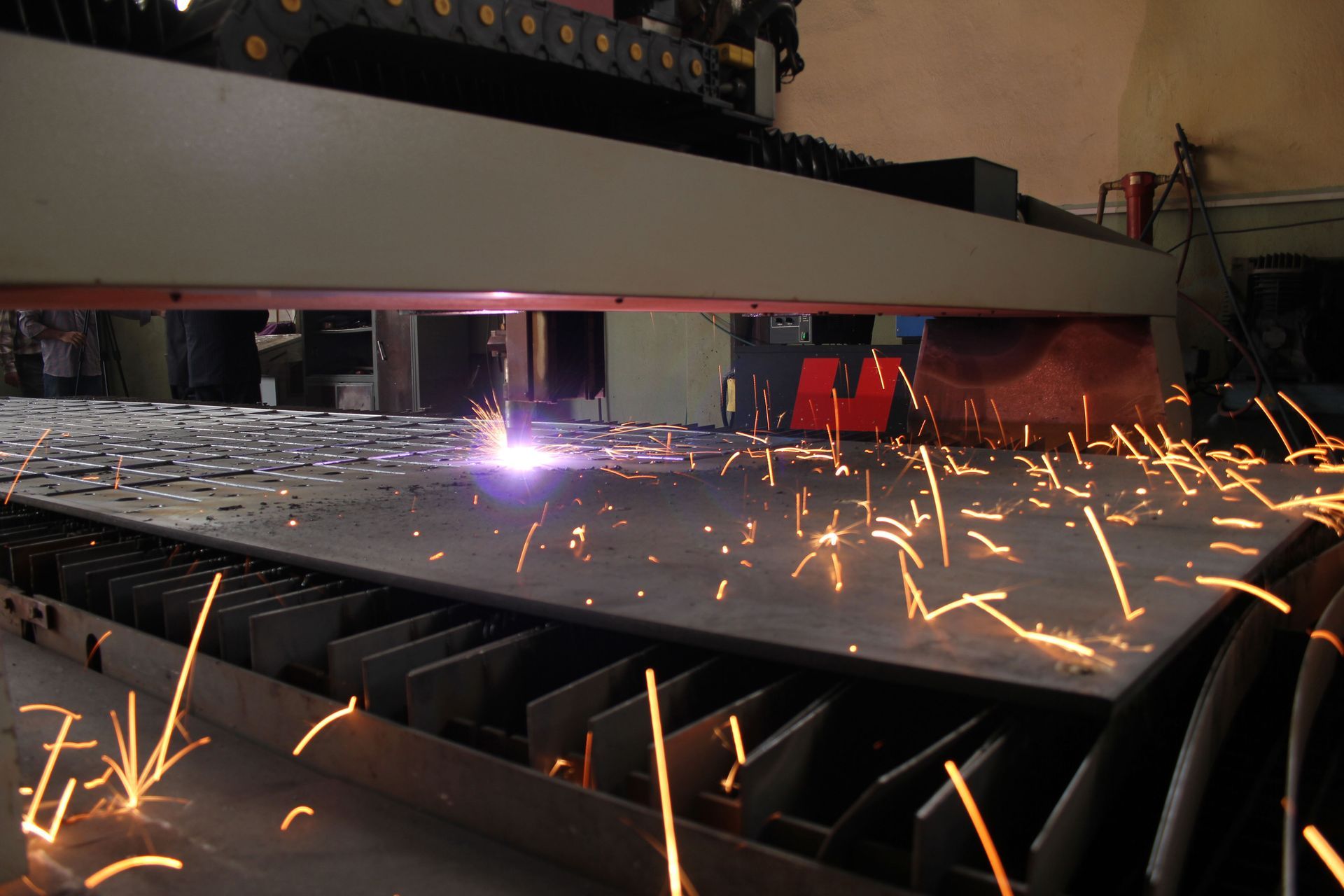

Rise of Automation and Smart Manufacturing Technologies

One significant trend in the metal parts manufacturing industry is the increasing adoption of automation and smart technologies. Automation not only increases production efficiency but also reduces error rates, leading to higher quality output. With the integration of technologies such as the Internet of Things (IoT) and artificial intelligence (AI), manufacturers can now streamline operations and enhance predictive maintenance capabilities. Companies embracing these technologies are better positioned to respond to the fast-paced demands of the global market.

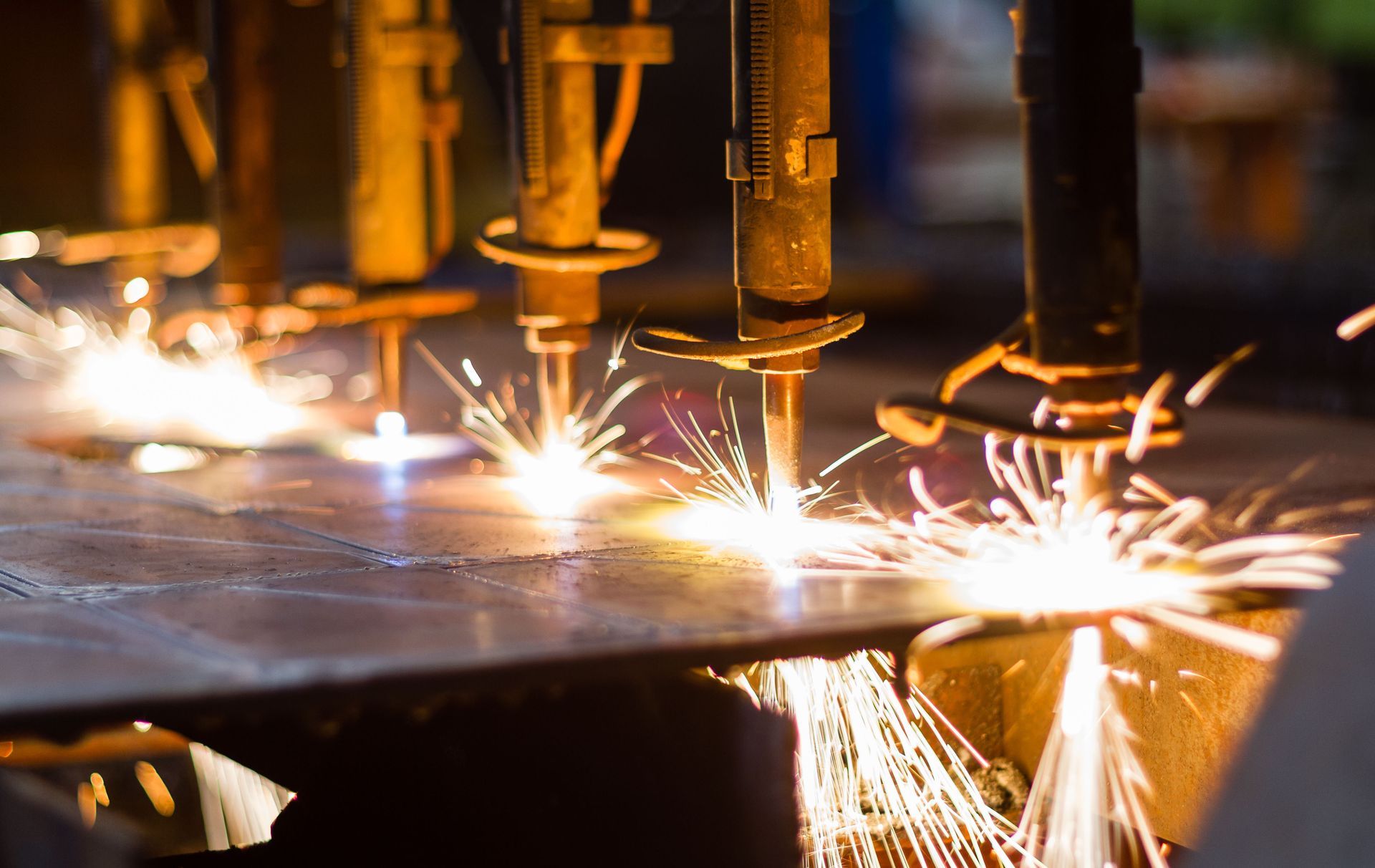

Rise of Demand for Skilled Welders and Workforce Development

The demand for skilled labor in the welding sector is also on the rise. According to JPS International, approximately 330,000 new welding professionals will be needed by 2028. This growing need highlights the industry's reliance on skilled craftsmanship despite advancements in automation. As experienced welders retire, opportunities for new generations of workers are appearing, underscoring the importance of vocational training and education in this field. Manufacturing companies are urged to invest in training programs to ensure a steady pipeline of skilled workers to meet future demands.

Rise of Sustainability Initiatives in Metal Parts Manufacturing

Environmental sustainability is another critical trend impacting metal parts manufacturing. With increasing regulatory pressures and consumer demand for eco-friendly products, manufacturers are adopting greener practices. This includes reducing waste through improved recycling processes, using sustainable materials, and optimizing energy efficiency within production facilities. Companies that prioritize sustainability not only contribute positively to the environment but also appeal to a growing segment of environmentally-conscious consumers.

Staying informed and adaptable to the current trends in the metal parts manufacturing industry is crucial for long-term success. As automation, skilled labor demands, and sustainability continue to drive the sector, businesses must be proactive in embracing these changes. By leveraging technology, investing in human capital, and committing to environmentally responsible practices, companies can ensure their competitiveness in an ever-evolving global marketplace. Ready to elevate your next project? Contact Denali MetalWorks today.

Share On: